How to Select the Right Strut Forming Line for Youur Needs?

How to Select the Right Strut Forming Line for Your Needs?

The manufacturing of strut channels is an essential part of modern construction and industrial applications. Strut channels are used in electrical installations, HVAC systems, mechanical supports, and countless other settings where reliable framing and structural reinforcement are needed. To meet this demand with efficiency and precision, manufacturers rely on advanced equipment such as the Strut Forming Line. This machinery transforms raw steel into strut channels of varying shapes and dimensions, ensuring that products are consistent, durable, and ready for diverse applications.

Selecting the right Strut Forming Line is a critical decision for manufacturers and contractors. The right equipment guarantees efficiency, cost savings, and long-term competitiveness, while the wrong choice can result in inefficiencies, increased costs, and compromised product quality. This article explores the key considerations when choosing a Strut Forming Line, including capacity, material compatibility, automation, customization, and sustainability.

Understanding the Strut Forming Line

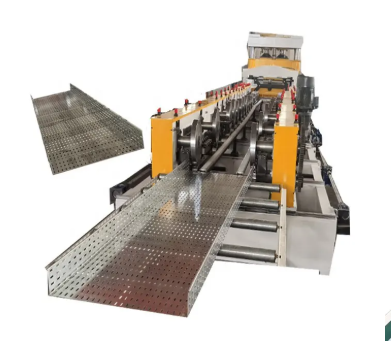

A Strut Forming Line is a specialized roll forming system designed to produce strut channels from coil steel. The process typically involves uncoiling, leveling, punching, roll forming, cutting, and stacking. The resulting channels may be plain or slotted, depending on the application. Strut channels are valued for their versatility, as they allow the mounting and supporting of equipment without the need for welding, offering flexibility in installation.

Modern Strut Forming Lines often include advanced automation and computer numerical control (CNC) systems. These features ensure that channels are produced with consistent dimensions, accurate hole placements, and clean cuts. By integrating different stages of production into one continuous process, these lines maximize efficiency while minimizing human intervention.

Production Capacity and Scalability

One of the most important factors when selecting a Strut Forming Line is production capacity. Manufacturers must evaluate the scale of their operations and determine how many channels they need to produce daily, weekly, or annually. A high-capacity line is ideal for large-scale operations serving national or international markets, while smaller, versatile lines may be more appropriate for regional manufacturers.

Scalability is also critical. Markets evolve, and demand can grow over time. Choosing a Strut Forming Line that can be upgraded or expanded ensures that the investment remains viable in the long term. Modular designs and flexible configurations help companies adapt production as business needs change.

Material Compatibility

Strut channels are typically produced from galvanized steel, stainless steel, or sometimes aluminum. The chosen Strut Forming Line must be compatible with the types of materials required by the target market. For example, electrical installations may prioritize corrosion-resistant stainless steel, while construction projects might focus on galvanized steel for durability and cost efficiency.

A line capable of handling multiple materials provides versatility and broadens the manufacturer’s client base. It is important to verify that the machine can process different material thicknesses, typically ranging from 1.5 mm to 3 mm, while maintaining accuracy and quality.

Precision and Quality Assurance

Strut channels must meet strict dimensional and structural requirements to ensure safety and performance in real-world applications. The Strut Forming Line should therefore include systems for monitoring precision at every stage, from punching to roll forming and cutting.

Integrated quality control systems, such as laser measurement and automated defect detection, help ensure that channels conform to specifications. Precision reduces material waste, prevents costly rework, and builds trust with customers who depend on consistent quality for their projects.

Automation and Efficiency

Automation is one of the defining features of modern Strut Forming Lines. Automated coil feeding, punching, and cutting significantly reduce manual labor, improve speed, and minimize errors. Computerized controls allow operators to program specifications easily and monitor production in real time.

Automation not only increases efficiency but also improves safety by reducing the need for operators to handle heavy materials manually. For high-volume manufacturers, advanced automation can make the difference between meeting deadlines and falling short of demand.

Customization and Flexibility

Every project may require different types of strut channels. Some need plain channels, while others require slotted designs with specific hole patterns. A Strut Forming Line that allows for customization provides significant advantages. Quick-change tooling, programmable punching systems, and adjustable roll stations enable manufacturers to switch between designs efficiently.

Flexibility ensures that manufacturers can meet diverse client requirements, from standard building projects to specialized industrial applications. This adaptability helps companies remain competitive in a market where customer demands are constantly evolving.

Durability and Maintenance

Since a Strut Forming Line is a significant investment, durability is essential. Machines built with robust frames, high-quality rollers, and reliable components are better equipped to handle continuous operation. Easy access for maintenance and modular construction also reduces downtime and ensures that machines remain in service for many years.

Regular maintenance is key to extending the lifespan of a forming line. Machines with predictive maintenance systems and automated lubrication features help reduce unexpected breakdowns, improve efficiency, and lower overall costs.

Energy Efficiency and Sustainability

Sustainability has become a major concern in modern manufacturing. Energy-efficient Strut Forming Lines help reduce operational costs and support environmental goals. By minimizing energy use, recycling scrap materials, and reducing waste, these machines contribute to greener production practices.

Manufacturers that prioritize sustainability in their production processes also enhance their reputation with customers who value environmentally responsible practices. Aligning production with global sustainability goals provides both a competitive and ethical advantage.

Cost and Return on Investment

While cost is always a consideration, it should not be the only deciding factor. A cheaper Strut Forming Line may save money upfront but lead to higher expenses later if it produces inconsistent quality, requires frequent maintenance, or cannot keep up with demand.

Manufacturers should consider total cost of ownership, including purchase price, operating costs, maintenance, energy consumption, and potential downtime. A higher-quality machine with reliable performance often delivers better long-term return on investment.

Applications of Strut Channels

Strut channels produced by forming lines are widely used in construction, electrical installations, and industrial support systems. They provide mounting solutions for piping, cabling, ventilation systems, and heavy machinery. Their modular design allows for quick installation and easy adjustments, making them a popular choice in projects that require flexibility.

Beyond construction and electrical applications, strut channels are also used in renewable energy projects, such as solar panel mounting systems, where durability and precise alignment are essential. The versatility of these products underscores the importance of selecting the right Strut Forming Line to meet varied market demands.

The Future of Strut Forming Lines

As technology advances, Strut Forming Lines will continue to evolve. The integration of artificial intelligence and IoT connectivity will enable predictive maintenance, real-time defect detection, and adaptive process control. Future machines will be even more energy-efficient, sustainable, and capable of producing increasingly complex designs with minimal manual intervention.

Manufacturers who invest in future-ready forming lines will not only improve productivity but also position themselves as leaders in an industry that values innovation and sustainability.

Conclusion

Selecting the right Strut Forming Line is a strategic decision that shapes the efficiency, quality, and competitiveness of any manufacturer involved in strut channel production. By considering factors such as production capacity, material compatibility, precision, automation, customization, durability, sustainability, and long-term return on investment, companies can ensure they make the right choice.

The right forming line does more than produce channels; it enhances reputation, secures client trust, and supports long-term growth. In an industry where reliability and efficiency are paramount, investing in the right Strut Forming Line is essential for success.

FAQ

What is a Strut Forming Line?

It is industrial equipment used to manufacture strut channels from steel coils through processes like uncoiling, punching, roll forming, and cutting.

Why is production capacity important?

Capacity determines whether a machine can meet current and future demand without overinvestment or underperformance.

Can one line handle multiple materials?

Yes, many modern lines can process galvanized steel, stainless steel, and sometimes aluminum, provided they are designed for material compatibility.

Why is precision so critical in strut channels?

Accurate dimensions and hole placements ensure safety, performance, and easier installation in real-world applications.

How does automation improve efficiency?

Automated feeding, punching, and cutting reduce manual labor, minimize errors, and allow faster, safer production.

What customization options are available?

Machines can be configured to produce plain or slotted channels with varying profiles and punching patterns, depending on client needs.

Are Strut Forming Lines durable?

Yes, if built with robust components and maintained regularly. Some machines also include predictive maintenance features to reduce downtime.

How do these machines support sustainability?

They minimize waste, recycle scrap, and use energy-efficient systems that align with global environmental goals.

What industries use strut channels?

They are used in construction, electrical installations, HVAC systems, renewable energy projects, and industrial support frameworks.

What future trends will shape Strut Forming Lines?

Artificial intelligence, IoT integration, advanced automation, and improved sustainability will define the next generation of forming lines.

EN

EN